Safeguarding the long-term integrity of surgical outcomes with W-bone™

Faster bone regeneration

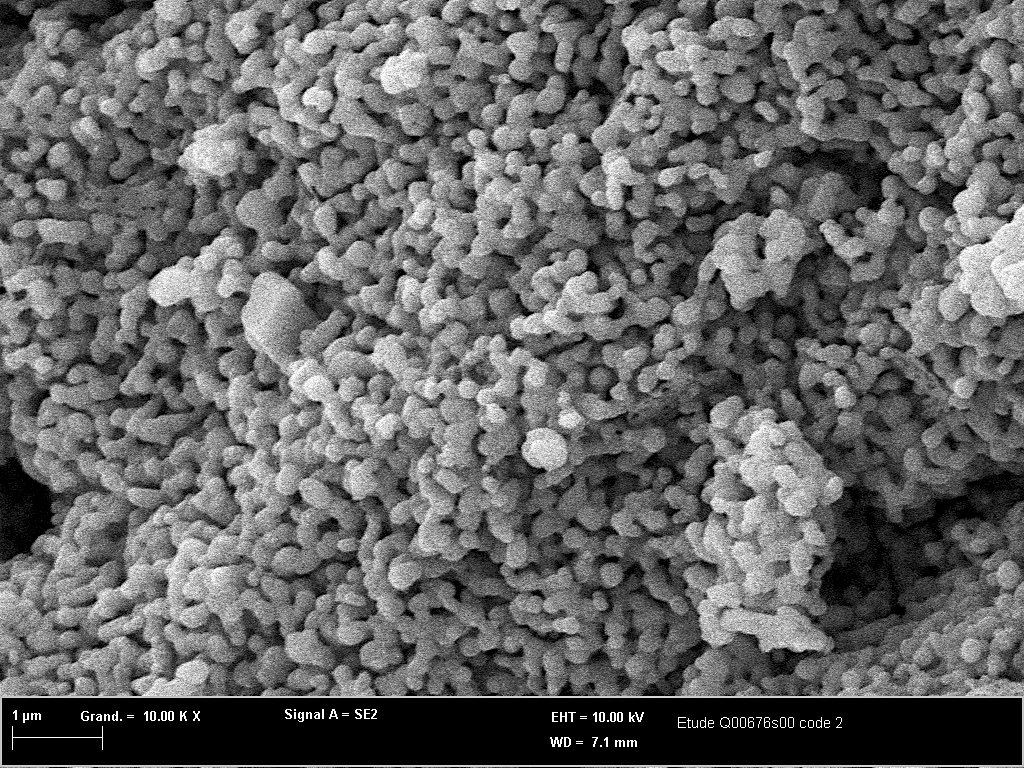

W-bone’s™ patented production process maintains the natural trabecular architecture and rough topography of bovine bone, enhancing its osteoconductive properties, bone graft mineralization, and healing speed.

Magnifiication W-Bone X 10,000

Patented manufacturing in Belgium

W-Bone™ bovine bone grafts are crafted entirely in Belgium, from inception through patented production to the final FDA-approved product.

Long-term stability you need - Fast remodelling your patient’s demand

Pure, safe and stable

Distinctive Healing Properties

The distinctive healing properties of W-Bone™ are attributed to its unique composition; larger pores of up to 2000 nm in size promote protein absorption and filopodia-mediated cell attachment, boosting permeability and accelerating dental graft remodelling.

For Clinicians, By Clinicians

W-bone™ xenograft is the result of a multidisciplinary collaboration between Professors from the University of Liège, Chemists, Biomedical Engineers and Clinical Experts in dental tissue engineering. Their objective was to define a process that guaranteed absolute safety while preserving the rough surface topography and natural surface chemistry of the bovine graft.

W-bone™ clinical indications and product codes

Filling of extraction sockets to enhance preservation of the alveolar ridge

Elevation of the maxillary sinus floor

Augmentation or reconstructive treatment of the alveolar process

Filling of infrabony periodontal defects

Filling of periodontal defects in conjunction with products intended for guided tissue regeneration and bone regeneration

Filling of defects after root resection, apicectomy and cystectomy

Filling of peri-implant defects in conjunction with products intended for guided bone regeneration

W-Bone Clinical indications

W-bone™ bovine xenograft consists of particles ranging in diameter from 0.25 to 1mm.

W-bone™ is available in the following weights:

| Product Name | Size (mm) | Mass (g) | Volume (cc) | ||||

|---|---|---|---|---|---|---|---|

| WHA025 | 0.25-1.0 | 0.25 | 0.5 | ||||

| WHA050 | 0.25-1.0 | 0.5 | 1.0 | ||||

| WHA100 | 0.25-1.0 | 1.0 | 2.0 | ||||

| WHA200 | 0.25-1.0 | 2.0 | 4.0 |

W-bone™ frequently asked questions

-

Nature's bony architecture is a wonderful work of art, and throughout the W-Bone production process, we take care to preserve the trabecular architecture of the native bovine bone.

Unlike conventional production techniques, the W-Bone manufacturing process takes place at controlled temperatures, ensuring the preservation of the bovine bone's micro and nano topographies.

-

W-Bone’s rougher surface promotes cell expansion by increasing the number of places on the bone topography where cells can adhere and interact. It is commonly accepted that rough implants have better osteoconductive qualities and increase the likelihood of successful osteointegration.

While most frequently used HA bone graft materials have pores smaller than 50 nm, W-Bone has pores as large as 2000 nm, improving protein adsorption and filopodia-mediated cell attachment.

W-Bone’s larger pores make scaffolds more permeable, benefiting nutrition absorption and osteoconductive characteristics.

The composition and surface chemistry of W-Bone distinguishes it from other commercially available products. Images of W-Bone particles at high magnification reveal crystal structures in its matrix that are derived from the magnesium found naturally in the bovine bone.

-

W-Bone’s manufacturing method preserves the mechanical and biological properties that nature has painstakingly crafted.

W-Bone’s increased intergranular and intragranular porosity improves osteoconductivity by allowing osteoblasts to attach. The resulting scaffolds have a high efficiency for bone regeneration due to the osteoblast promotion and vascularization features.

Significant efforts are made to ensure the complete deactivation of infectious agents. TSE agents and viruses are the two main targets in the W-Bone manufacturing process.

TSE agents are inactivated by extracting them under high pressure and temperatures in an alkaline solvent. In the final stages of W-Bone production, we also sinter to completely remove all organic residues, including prions.

-

The European Directorate for the Quality of Medicine and Healthcare has given W-Bone a Certificate of Suitability. W-Bone has also undergone testing in accordance with ISO 10993 series.

W-Bone has been established as non cytotoxic, sensitising, irritating, pyrogenic, poisonous, or mutagenic.

We rigorously follow the guidelines set out by the US FDA and we are certified to ISO 13485 standard.

We also conclude from solid preclinical and clinical research that W-Bone stands out as a very safe xenograft within the marketplace.